описание

|

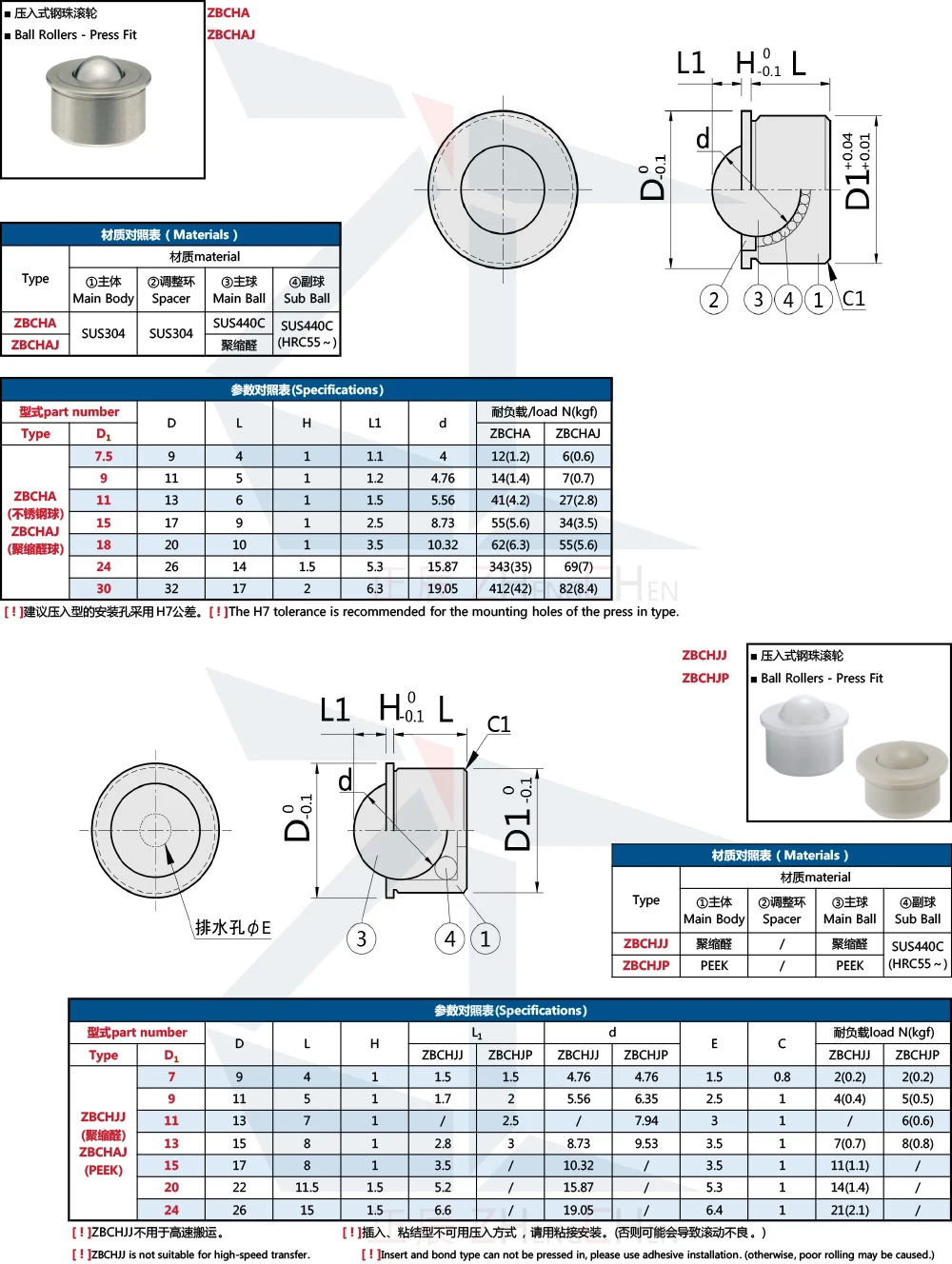

наименование продукта

|

Производители оборудования для крепежных элементов

|

||||||

|

профессиональное внимание

Крепление оборудования

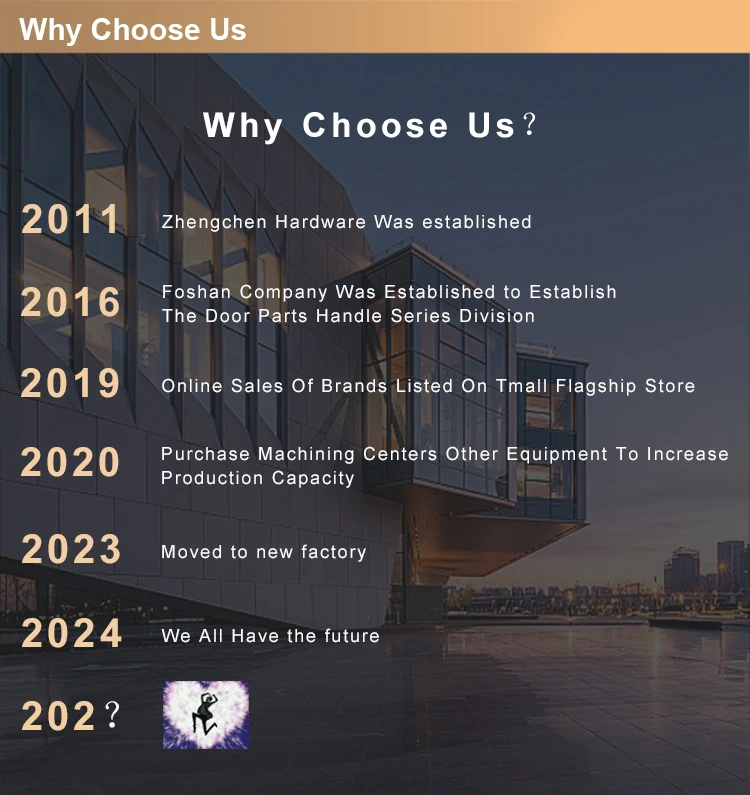

Снис 2011✌

|

шаровой пленгер/пружечные пленгеры из нержавеющей стали/ручной выдвижной пружинный пленгер/пружечно загруженный пленгер/мультипролетный пленгер/короткий микропружечный пленгер/минииндексирующий пленгер/устройство

Одноразовый сервис ~~

Один за бесплатные образцы ~~ Не стесняйтесь, свяжитесь с нами бесплатно!

Это будет прекрасное начало для нас.

|

||||||

|

упаковка

|

мешки из пвк для надувных или картонные для духов или по инструкции клиента

|

||||||

|

морское судоходство

|

морским, воздушным или экспресс-посольством

|

||||||

|

порт

|

Шэньчжэнь, Гонконг, Гуанчжоу

|

||||||

|

время доставки

|

7 дней - 15 дней

|

||||||

|

оплата

|

t/t,50% депозит,50% остаток перед доставкой,West Union,paypal и т.д.

|

||||||

|

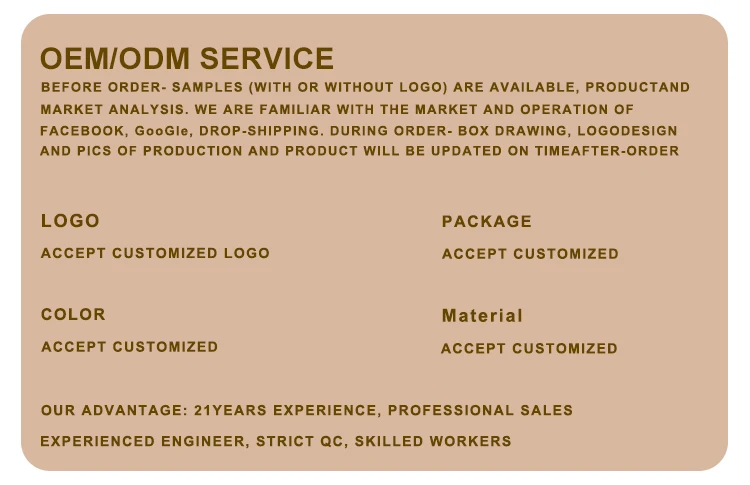

обычай

|

OEM/ODM

|

||||||

EN

EN

AR

AR

CS

CS

NL

NL

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

VI

VI

TH

TH

TR

TR

MS

MS

IS

IS

BN

BN

MN

MN

NE

NE