Description

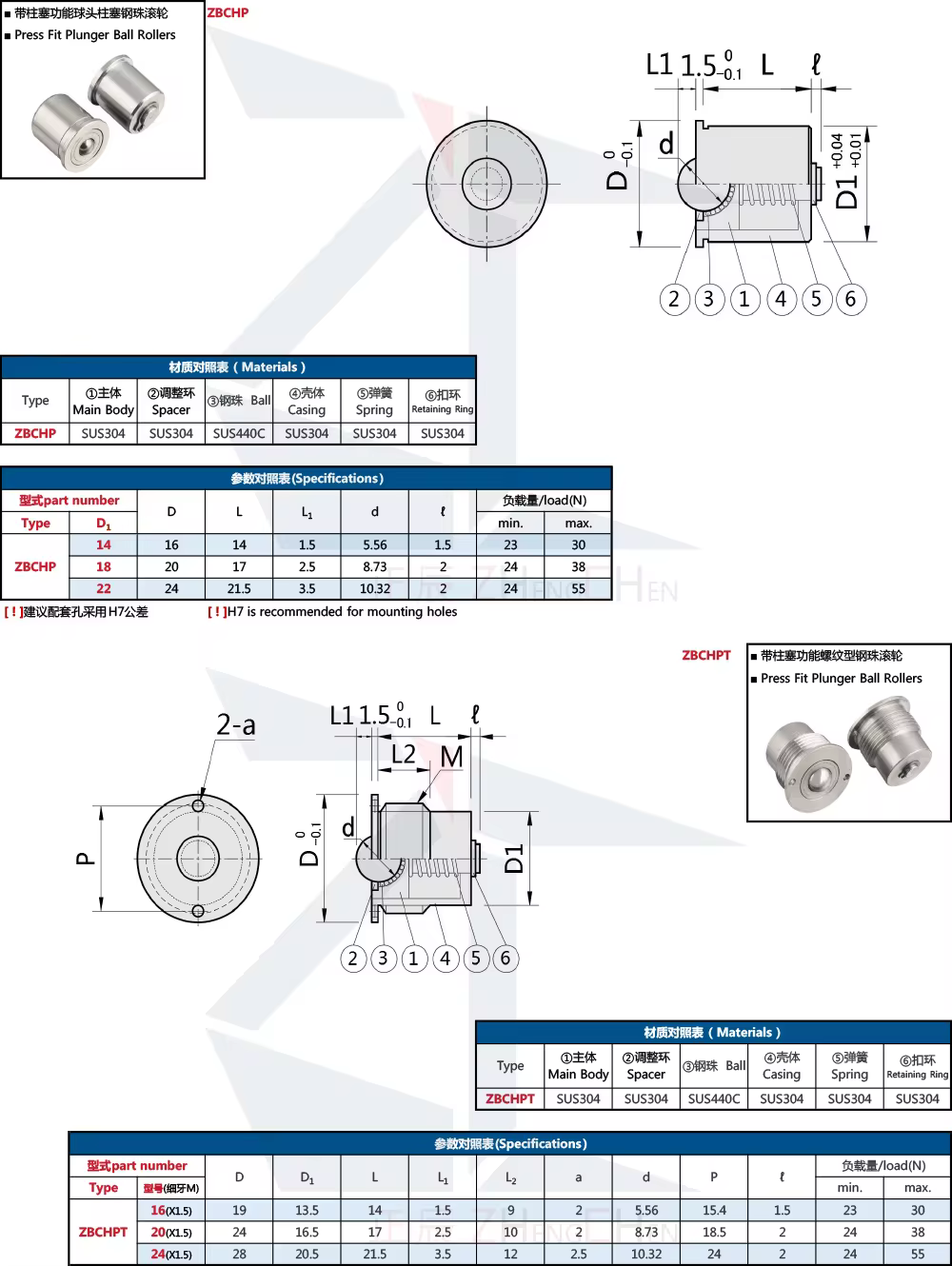

Steel ball roller is a type of ball used for conveying and changing the direction of the conveying object, mainly used in transmission devices on automated production lines. It is a very important metal accessory in automated assembly lines, which can help products transport and move on the assembly line.

The characteristics of steel ball rollers include:

1. High precision:

The precision of steel ball rollers meets strict standards, and they are easy to replace even if damaged.

2. Excellent load-bearing performance: Steel ball rollers made from machined stainless steel or resin are more durable than those made by pressing.

3. Flexible rotation:

They can change the direction of transmission at will.

4. Compact size:

Suitable for installation in tight spaces.

5. Resistant to rust and corrosion:

Made of stainless steel and other materials, they are highly practical.

6. Self-cleaning and easy to clean:

Suitable for use in the food industry.

Steel ball rollers have wide applications in various industries such as electronics, hardware, machinery, chemicals, food, forestry, mining, books, supermarkets, rubber, etc., in their conveying systems, feeding systems, processing systems, processing machinery, and packaging machinery auxiliary equipment. They can be used in various linear or multi-directional conveying occasions, such as production lines, work platforms, workbenches, and conveyor lines.

EN

EN

AR

AR

CS

CS

NL

NL

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

VI

VI

TH

TH

TR

TR

MS

MS

IS

IS

BN

BN

MN

MN

NE

NE