説明

|

名前

|

ステンレス鋼 GN614-NI スムースボールスプリングプランジャー

|

||||||

|

材料

|

ステンレス鋼

|

||||||

|

特徴

|

GN614

|

||||||

|

関連生産の特徴

|

関連製品の特徴 ボールプランジャー/スプリングプランジャー ステンレススチール/手動引き込み式スプリングプランジャー/スプリング式

プランジャー/ボールスプリングプランジャー/ショートマイクロスプリングプランジャー/ミニインデックスプランジャーピン/ボールトランスファーユニットスプリング式ローラー/スプリング ロードロックピン/ヘビーデューティーボールプランジャー/ヘビーデューティースプリングプランジャー |

||||||

|

梱包

|

インフレータブル用のPVCバッグ、ブロワー用のカートン、または顧客の指示に従って

|

||||||

|

輸送

|

海上、航空、エクスプレス

|

||||||

|

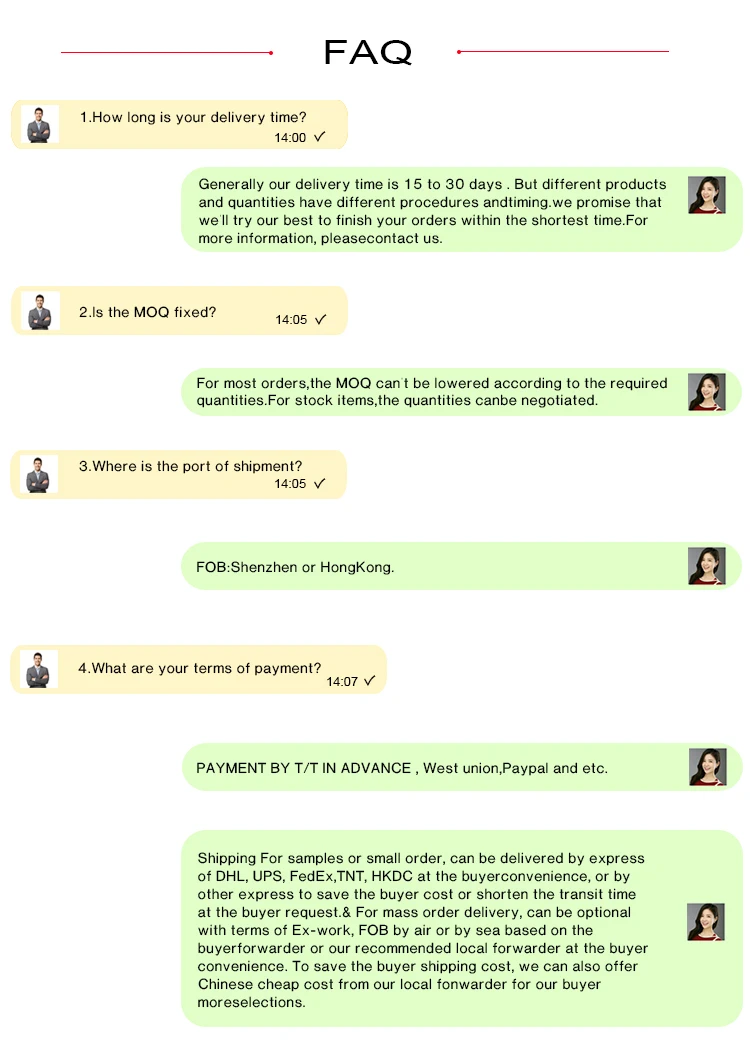

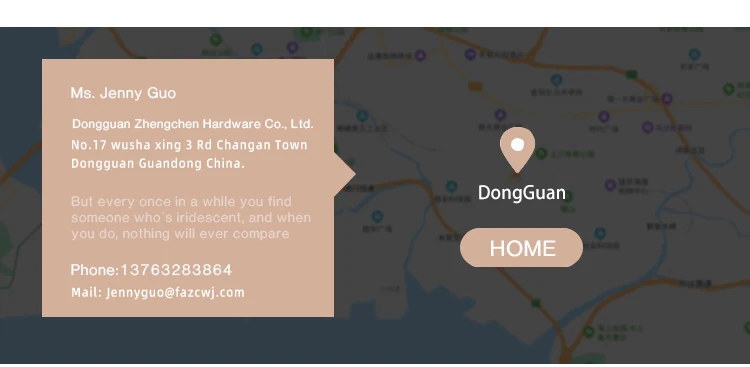

港

|

深センまたは香港

|

||||||

|

納期

|

5日間~10日間

|

||||||

|

納期

|

15日~30日

|

||||||

|

支払い

|

T/T、50%のデポジット、配達前に50%の残額を支払う、ウェストユニオン、PayPalなど

|

||||||

|

カスタム

|

製造・販売

|

||||||

EN

EN

AR

AR

CS

CS

NL

NL

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

VI

VI

TH

TH

TR

TR

MS

MS

IS

IS

BN

BN

MN

MN

NE

NE