Shoulder Bolts: Their Importance and Application in Engineering

Understanding Shoulder Bolts: Structure and Functionality

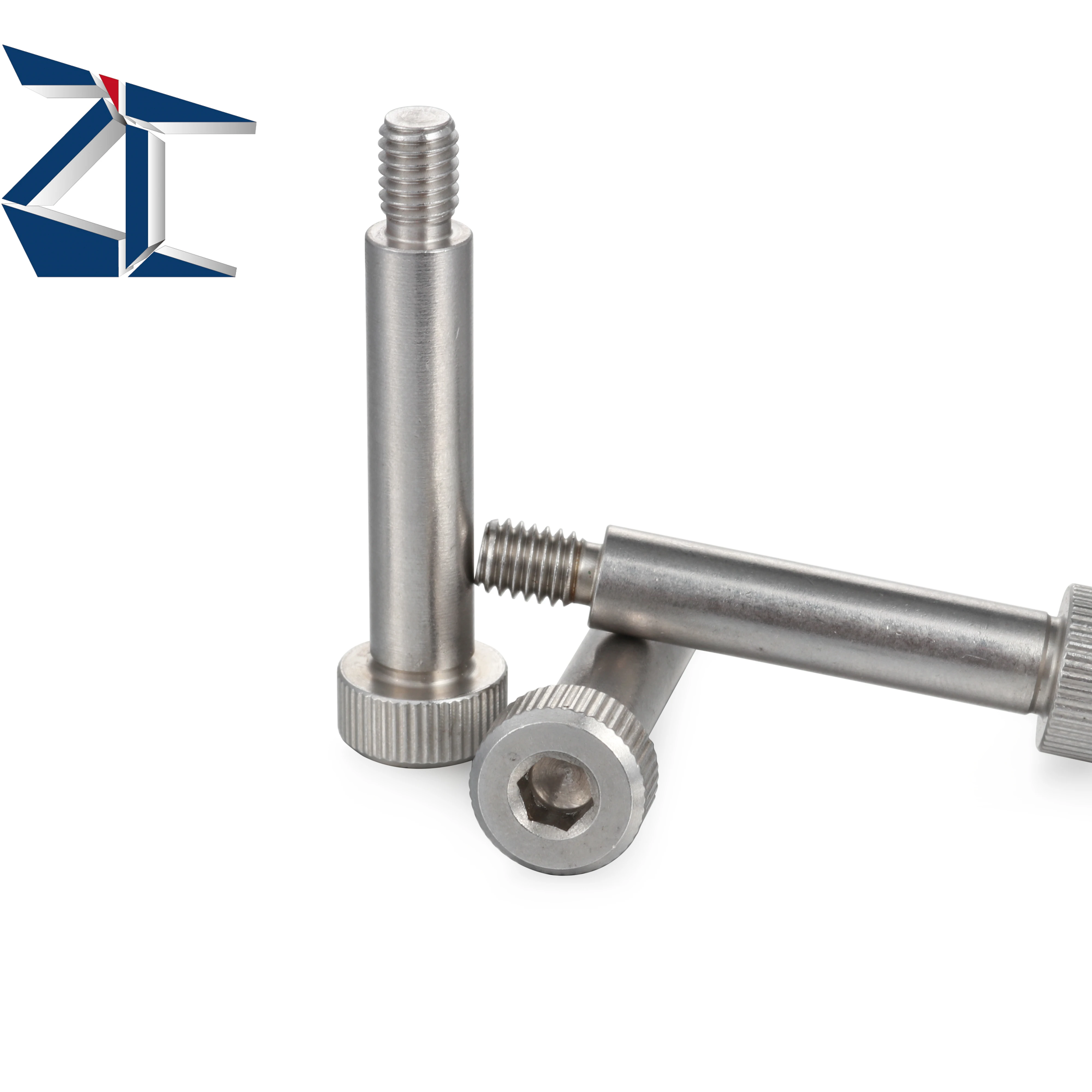

Shoulder bolts, also known as shoulder screws, are unique fasteners designed with a distinctive structure that includes a cylindrical shoulder between the head and the shank. This unthreaded shoulder provides a precise pivot and load-bearing surface, making them essential in applications requiring accurate alignment and smooth rotational or sliding motion. The shoulder bolt's distinctive design enables it to function effectively in diverse mechanical systems, where precision and stability are crucial.

Key features of shoulder bolts include their resistance to bending and shear forces, primarily due to the robust cylindrical shoulder. This feature enhances their load-bearing capacity, making them preferable in demanding applications. Furthermore, shoulder bolts are manufactured to standardized dimensions, allowing seamless integration across various mechanical systems. They are also produced from materials like stainless steel, alloy steel, and brass, catering to different strength and corrosion resistance needs. These material options make shoulder bolts highly versatile, suitable for environments ranging from mild to harsh conditions.

In conclusion, the precision, standardized sizing, and material flexibility of shoulder bolts make them indispensable in industries such as automotive, aerospace, and machinery, where both reliability and performance are mandatory. Their unique structure ensures they remain a cornerstone in component assemblies requiring pivots or guides.

Importance and Application of Shoulder Bolts in Engineering

Shoulder bolts, often called the unsung heroes of mechanical systems, are pivotal in engineering due to their versatile roles. They act as pivot points and offer removable or fixed support, contributing significantly to the stability of assemblies, which is crucial in complex machinery. This makes them invaluable in applications that require precise movement or alignment, such as in automotive suspensions, machinery, and aerospace control systems.

The benefits of using shoulder bolts in engineering are numerous. Firstly, their versatility allows them to be used across a broad range of applications, from light-duty tasks to heavy industrial processes. Secondly, shoulder bolts boast a high load capacity, which is vital for supporting substantial mechanical loads while ensuring seamless motion and interaction among moving parts. This feature is key when dealing with dynamic loads, reducing both maintenance costs and system downtime.

Moreover, the ease of assembly and disassembly makes shoulder bolts ideal for applications where frequent adjustments or replacements are anticipated. For instance, in the manufacturing industry, where machinery components are routinely replaced or adjusted, shoulder bolts facilitate this process with their design, saving time and labor costs. Overall, the adaptability of shoulder bolts to varying operational demands underscores their role as indispensable components in modern engineering.

Types of Shoulder Bolts and Their Specific Applications

Shoulder bolts come in various types, each suited to specific applications. Commercial shoulder bolts are the most commonly used, ideal for general applications due to their standard sizes and specifications. This makes them easy to source and replace across many different projects. They serve as reliable components in applications ranging from furniture assembly to small machinery, where their role is more focused on basic alignment and aiding in sliding tasks.

On the other hand, precision shoulder bolts are crafted for high-tolerance applications that demand improved accuracy and reliability. These bolts are especially essential in industries such as robotics and intricate machinery, where precision in alignment and movement is crucial. Precision shoulder bolts ensure that components align correctly and move smoothly without unwanted play, making them indispensable in advanced engineering sectors.

Materials Used in Manufacturing Shoulder Bolts

Shoulder bolts are manufactured using materials like stainless steel, mild steel, and specialty alloys, each offering distinct properties for various applications. Stainless steel is prized for its durability and excellent corrosion resistance, making it suitable for environments exposed to moisture or chemicals. It is often used in food processing equipment where the ease of cleaning and resistance to rust are critical. Mild steel, known for its affordability and adequate strength, is used where cost-efficiency is a primary consideration, but it lacks the superior corrosion resistance seen in stainless steel. Specialty alloys such as titanium or alloy steel enhance strength, durability, and resistance to extreme conditions, ideal for high-stress applications like aerospace or automotive industries.

When selecting the appropriate material for shoulder bolts, consider factors like load capacity, environmental exposure, and the performance characteristics needed for your application. For instance, environments requiring corrosion resistance benefit from stainless steel shoulder bolts. For high-load applications in construction or heavy machinery, alloy steel is often preferred due to its enhanced mechanical properties. By aligning the material choice with specific operational demands, you can ensure optimal performance and longevity of shoulder bolts in any engineered system.

Practical Examples of Shoulder Bolt Applications in Various Industries

Shoulder bolts are integral to the smooth and safe operation of numerous industries due to their unique design and ease of use. In the automotive and aerospace sectors, these bolts are vital in assembling complex systems such as control mechanisms and structural supports. Here, they ensure that components work seamlessly even under substantial stress, playing a crucial role in maintaining both safety and functionality. For instance, in automotive applications, shoulder bolts help in tasks like mounting pivot points and joining linkages, contributing to vehicle stability and reliability.

Similarly, in the field of medical devices and equipment, shoulder bolts serve as essential components for precision assembly and operation. The demanding nature of medical environments, where reliability and durability are paramount, necessitates the use of high-quality fasteners. Shoulder bolts are used in medical equipment to secure joints and allow for adjustments without compromising on component integrity. Their application in this domain ensures that equipment functions accurately and safely, meeting the industry's rigorous standards for performance and reliability.

Top Shoulder Bolt Products for Engineering Needs

When it comes to engineering applications, having the right type of shoulder bolt can make a significant difference. Custom stainless steel shoulder bolt hexagon socket shoulder screw bolts are tailored to meet specific engineering requirements, providing enhanced performance in specialized applications. Their design focuses on durability and adaptability, making them ideal for challenging environments where precision and strength are crucial.

Hot sale products like shoulder bolt step screws in varied sizes—M3, M4, M5, M6, M8, M10—are in high demand among manufacturers for general assembly requirements. These versatile fasteners provide reliability and flexibility, allowing them to meet a wide array of industrial needs, from small-scale projects to large manufacturing processes.

Professional suppliers provide shoulder screws with metric measurements, such as stainless steel hex socket head shoulder screw bolts. These products ensure accuracy and facilitate ease of inventory management in engineering projects. They cater to the precision demands of the engineering sector, where maintaining tight tolerances and specifications is critical.

EN

EN

AR

AR

CS

CS

NL

NL

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

VI

VI

TH

TH

TR

TR

MS

MS

IS

IS

BN

BN

MN

MN

NE

NE